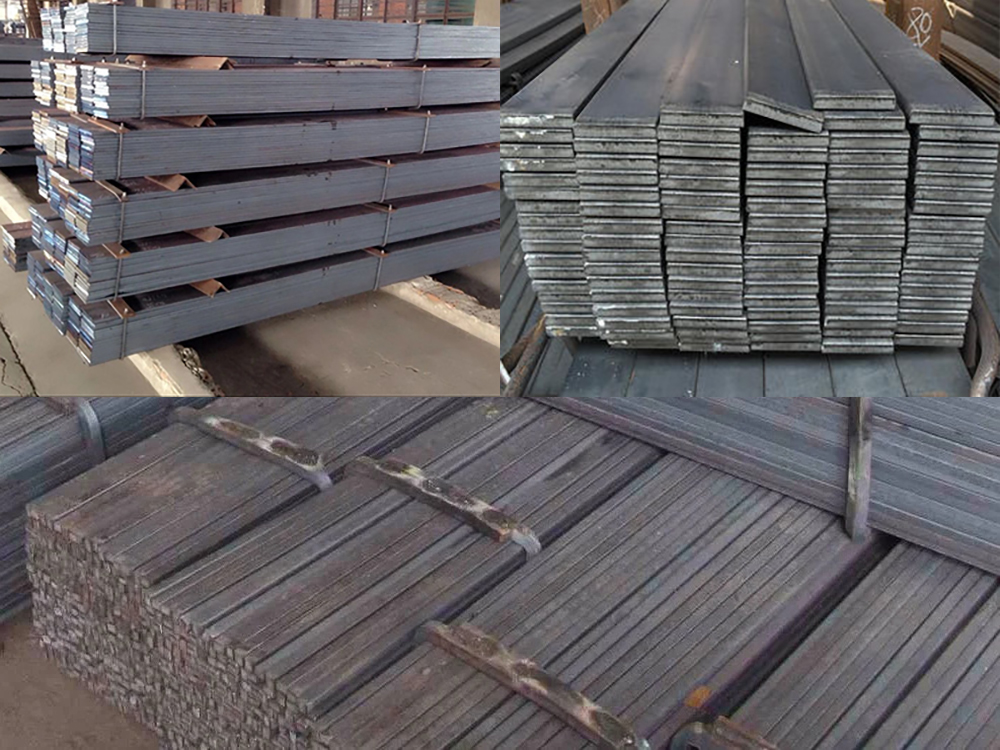

Flat Steel Q235 Iron Flat Iron Rectangular Flat Bar

| Product Name | Hot-Rolled Carbon Steel Flat Bar |

| Specification: | AiSi ASTM bs DIN GB JIS |

| Material | Q235 |

| Technique | Hot Rolled |

| Surface treatment | Galvanized, Annealed |

| Payment terms | 30% T/T deposit in advance, 70% T/T balance within 5 days after B/L copy, 100% Irrevocable L/C at sight, 100% Irrevocable L/C after receive B/L 30-120 days |

| Delivery times | Delivered within 30 days after receipt of deposit |

| Package | 1. Packed with bundles tightened with metal belt if need |

| Loading port | Xingang, China |

| Application | Widely used in building structures and industrial structures |

| Advantages | 1. Reasonable price with excellent quality 2. Abundant stock and prompt delivery

3. Rich supply and export experience, sincere service |

I. Hot-rolled Flat Steel Bar(Mainstream Process, Suitable for Large-Size, Low-Cost Demands)

1. Raw Material Preparation: Select qualified steel billets (mostly continuously cast billets, materials such as Q235, Q355, stainless steel, etc.), check the dimensions and surface quality of the billets, and remove defects such as cracks and inclusions.

2. Heat Treatment: Send the steel billets into a walking beam furnace and heat them to 1100–1250℃ to homogenize the internal structure of the billets, improve plasticity, and facilitate rolling.

3. Rolling and Shaping: The heated steel billets are rolled in multiple passes through a roughing mill and a finishing mill to gradually roll them into flat steel of the target thickness and width.

Roughing: Reduces the cross-section of the steel billet, providing initial shaping;

Finishing: Controls dimensional accuracy (thickness tolerance up to ±0.1mm) and surface flatness.

4. Cooling and Straightening: The rolled flat steel is air-cooled or controlled-cooled to room temperature, and then straightened by a straightening machine to correct bending deformation and ensure straightness.

5. Finishing

Surface Cleaning: Remove oxide scale and burrs, using pickling, shot blasting, or grinding processes;

Fitting to Fixed Lengths: Cut to fixed lengths according to customer requirements (e.g., 6m, 9m, 12m);

Quality Inspection: Check dimensional tolerances, mechanical properties, and surface quality; reject defective products.

Iron flat bar, as a commonly used structural steel product, has core characteristics concentrated in four dimensions: cross-sectional shape, dimensional accuracy, mechanical properties, and processing adaptability. The characteristics of hot-rolled and cold-rolled products differ significantly:

1. Fixed Cross-Sectional Characteristics: The cross-section is a regular rectangle (with slightly rounded edges), with a stable thickness-to-width ratio, and an overall elongated shape. Compared to round steel and angle steel, it has a larger planar contact area, making it suitable for use as load-bearing connectors, grounding electrodes, etc.

2. Flexible Dimensions and Graded Precision:

(1) Hot-rolled flat steel: Wide range of specifications, thicknesses from 2–60mm and widths from 10–200mm can be produced. Dimensional tolerances are relatively loose, meeting the large-scale requirements of construction and steel structures.

(2) Cold-rolled flat steel: Thickness from 0.2–4mm and width from 5–100mm, high dimensional accuracy (thickness tolerance ±0.05–0.1mm), smooth surface without oxide scale, suitable for precision machinery manufacturing.

3. Strong adaptability to processing and installation: It can be directly cut, drilled, welded, bent and other processed without complicated pretreatment; the weight is uniform, which is convenient for transportation and on-site installation, and it is widely used in steel structure support, mechanical parts, building grounding devices, shelf beams and other scenarios.

The core advantages of flat steel bar are its wide range of specifications, low cost, moderate strength, and convenient processing.

1. Building and Steel Structure Engineering: Supporting components and connectors for steel structure workshops, such as auxiliary reinforcement of purlins and lateral support for frame beams;

2. Basic Components in Machinery Manufacturing: Bases and frames of large equipment, such as the frame structure of crushers and conveyors, which can be directly welded and drilled without precision machining;

3. Structural Components for Agricultural and Construction Machinery, such as chassis supports for tractors and auxiliary load-bearing components for excavators;

4. Infrastructure Construction: Embedded components for bridges and tunnels, used to fix guardrails and pipeline supports; Crossarms and supports for transmission towers and communication base stations, supporting cables and signal equipment;

5. Other Fields: Reinforcing components for ship decks, frame supports for containers; Raw materials for hardware products, which can be further processed into simple parts through cutting and grinding.

Please leave your company messages, we will contact you soonest.