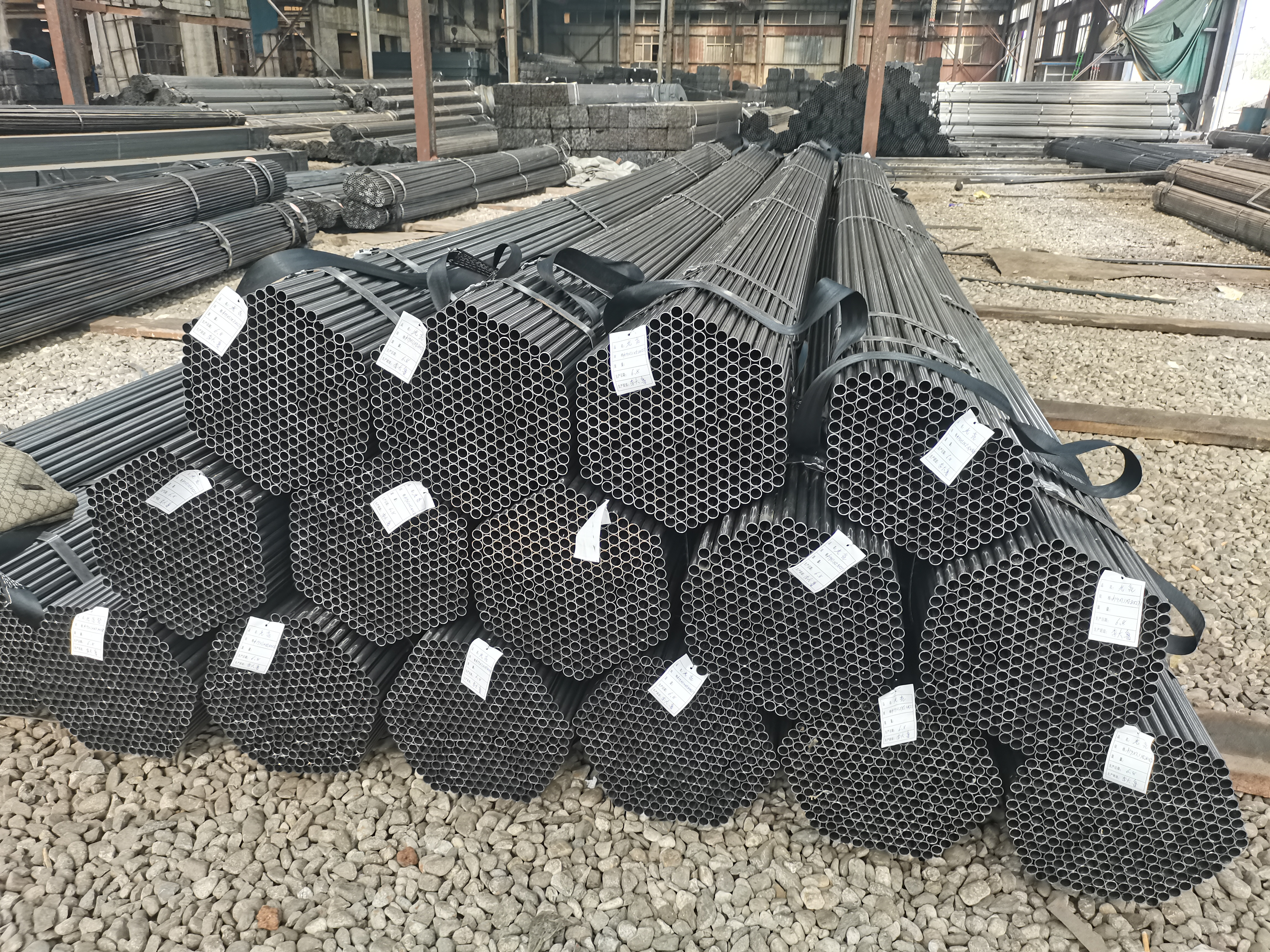

Black round iron pipe is a common type of metal pipe with a wide range of applications. Here is a detailed introduction:

1. Definition and Material: Black round iron pipe generally refers to round iron pipes with a black surface. Its material is typically carbon steel, commonly Q195, Q235, and Q345.

2. Specifications and Dimensions

Outer Diameter: Various sizes are available, commonly 1/2 inch (approx. 20mm), 3/4 inch (approx. 25mm), and 1 inch (approx. 32mm), with an outer diameter tolerance of ±0.5mm.

Wall Thickness: A wide range of thicknesses are available. For example, a 1/2-inch round iron pipe can have a wall thickness between 0.6-3.0mm, with a wall thickness tolerance of ±0.1mm.

Length: Typically available in lengths from 3.0 to 12.0 meters, with a length tolerance of 0 to +20mm.

3. Manufacturing Process

Seamless Steel Pipes: Manufactured through processes such as piercing, hot rolling, and cold rolling. The pipe body has no weld seams, boasts high strength, and is suitable for high-pressure, high-precision applications, such as oil transportation and machinery manufacturing.

Welded Steel Pipes: Steel strips are rolled into cylindrical shapes and then welded together, such as ERW (resistance welded) steel pipes. This method offers high production efficiency and lower cost, and is widely used in construction, water, electricity, and gas transmission, and other fields.

4. Surface Treatment

The black color of black round iron pipes is usually achieved through surface treatments such as painting and hot rolling. Painting provides corrosion and rust prevention while giving it a black appearance; hot rolling creates an oxide scale on the steel surface, also resulting in a black color.

5. Application Areas

Construction Industry: Used for scaffolding and structural support.

Pipeline Systems: Can be used to transport fluids such as water, gas, and oil.

Furniture Manufacturing: Due to its ease of bending and shaping, it is often used to make furniture frames, table legs, chair legs, etc.

Machinery Manufacturing: Used as raw material for mechanical parts, such as shafts and sleeves.

6. Advantages and Disadvantages

Advantages: High strength and hardness, good compressive and bending resistance, relatively good corrosion resistance, and easy to process and connect.

Disadvantages: Compared to some non-ferrous metal pipes, it is heavier, more prone to rust, and requires appropriate anti-corrosion treatment.

Post time: Jan-09-2026