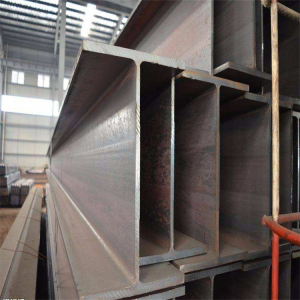

Hot Rolled Structural Steel Profile H Beams H Shaped Hollow Section for Building

| Product Name | Hot Rolled Structural Steel Profile H Beams |

| Size | 100*100-900*300mm(or pls see follow specification) |

| Material | Q235B, Q235C, Q345 |

| Technique | Hot Rolled |

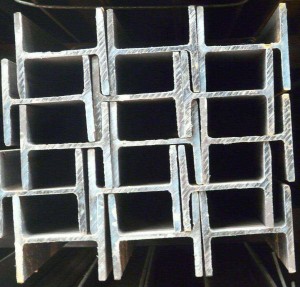

| Surface treatment | Galvanized, Color Painting |

| Payment terms | 30% T/T deposit in advance, 70% T/T balance within 5 days after B/L copy, 100% Irrevocable L/C at sight, 100% Irrevocable L/C after receive B/L 30-120 days |

| Delivery times | Delivered within 30 days after receipt of deposit |

| Package | 1. Packed with 8 bundles tightened with metal belt if need |

| Loading port | Xingang, China |

| Application | Widely used in building structures and industrial structures |

| Advantages | 1. Reasonable price with excellent quality 2. Abundant stock and prompt delivery

3. Rich supply and export experience, sincere service |

Hot-rolled H-beams (Mainstream Common Process)

- Bill Preparation: Select continuously cast billets of the corresponding material (e.g., Q235, Q355), and inspect for surface defects.

- Heating: Send the billet into the heating furnace and heat it to 1200-1300℃ to ensure uniform and thorough heating.

- Rolling: First, rough roll to open the billet and widen the flanges, then finish roll to shape it, controlling the cross-sectional dimensions through multiple passes of rolls.

- Cooling: Natural cooling or controlled cooling to avoid rapid cooling that could cause cracks.

- Straightening: Use a straightening machine to correct bending and twisting deformations to ensure straightness.

- Cutting: Cut to length according to customer requirements, removing excess edges and corners.

- Inspection: Inspect dimensional accuracy, mechanical properties, and surface quality; after passing inspection, store in the warehouse.

The core characteristics of H-beams are their superior cross-sectional mechanical properties, wide range of applications, and convenient construction, making them one of the most widely used steel profiles in steel structures.

1. Structural and Mechanical Advantages: The H-shaped cross-section, thin web, and wide flanges result in high bending and torsional stiffness, leading to superior load-bearing efficiency compared to I-beams and channel steel of the same weight.

Lightweight yet with high load-bearing capacity, reducing the overall building weight and lowering foundation costs.

The uniform stress distribution across the cross-section allows for full utilization of the steel's strength (e.g., the high strength of Q355 steel).

2. Construction and Usage Advantages: Regular shape facilitates cutting, welding, and assembly, resulting in high on-site construction efficiency and shorter construction periods.

Customized specifications are available (hot-rolled standard specifications, welded non-standard large cross-sections) to suit various scenarios.

Large surface area ensures good adhesion to concrete and fire-retardant coatings, facilitating fireproofing and corrosion protection.

3. Wide Range of Applications: Building engineering: Frame structures and supporting components for factories, bridges, and high-rise buildings.

Mechanical Manufacturing: Equipment bases, supports, conveyor machine frames.

Municipal Engineering: Streetlight poles, billboard supports, underground utility tunnel supports.

4. Other Features: Hot-rolled H-beams are integrally formed, offering good toughness and durability, suitable for long-term load-bearing applications.

Welded H-beams allow for flexible adjustment of cross-sectional dimensions, meeting non-standard requirements for special projects.

Cold-formed H-beams offer thin wall thickness and high precision, suitable for lightweight steel structures (such as prefabricated houses and exhibition halls).

1. Building Construction (Main Application Area)

Industrial Buildings: Main frames, crane beams, and columns for factories and warehouses, capable of supporting the weight of large equipment and crane loads.

Civil Buildings: Steel structural frames for high-rise buildings, office buildings, and apartments, reducing building weight and improving seismic performance.

Public Buildings: Large-span structures for convention centers, stadiums, and airport terminals, achieving column-free open spaces.

Lightweight Buildings: Load-bearing frames for prefabricated houses and light steel villas, combined with cold-formed H-beams, balancing lightness and stability.

2. Bridge Engineering

Main beams, crossbeams, and support structures for small and medium-sized bridges, replacing traditional concrete components, reducing bridge weight and shortening construction time.

Ramp supports and pier supports for overpasses and viaducts, improving structural deformation resistance and durability.

3. Machinery Manufacturing and Equipment

Equipment Bases and Frames: Support bases for machine tools and heavy equipment, ensuring stability during operation.

Conveying Machinery: Belt conveyors, crane frames and beams, suitable for long-term stress and vibration environments.

Construction Machinery: Excavator and tower crane booms and support components, utilizing high-strength H-beams to enhance load-bearing capacity.

4. Municipal and Infrastructure Engineering

Underground Utility Tunnels: Support frames and cover plate load-bearing structures for utility tunnels, corrosion-resistant and easy to install and maintain.

Municipal Facilities: Streetlight poles, billboard supports, traffic sign poles, using cold-formed or small hot-rolled H-beams, balancing strength and aesthetics.

Ports and Terminals: Container stacking supports, loading and unloading equipment track beams, resistant to sea wind corrosion and heavy-load impacts.

5. Other Special Applications

Temporary Works: Construction scaffolding and formwork support systems, easy to assemble and disassemble and reusable.

Marine Engineering: Auxiliary support components for near-shore platforms, requiring anti-corrosion treatment to meet marine environmental requirements.

Wind Power Engineering: Lower tower sections and nacelle supports for wind turbines, suitable for harsh outdoor environments and heavy-load requirements.

Please leave your company messages, we will contact you soonest.